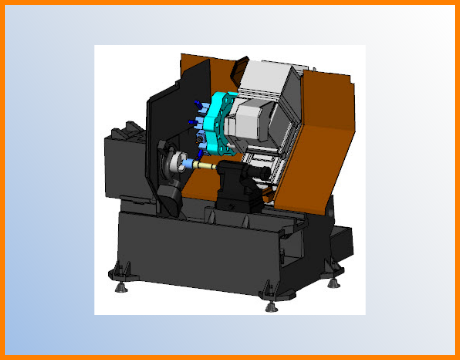

MILL TURN

Program your CNC Mill Turn parts right inside of SOLIDWORKS™!

The new BobCAM for SOLIDWORKS™ Mill Turn software is a complete multitask CAM add-on that combines all of the powerful CNC programming functionality of both mill and lathe into a single streamlined C axis machining solution. BobCAM for SOLIDWORKS™ multitask CNC software delivers high performance features in an easy to use interface designed to meet the complex programming demands of mill turn machining.

NEW FEATURE: Job Templates

BobCAM’s New Job Templates allow you to program faster with fewer clicks. Save your stock, set up location, machining features and more. Great for similar projects, part revisions, and standard processes. Get more done with fewer steps using BobCAM V8.

BobCAM for CNC MILL FEATURES

TEST DRIVE our Powerful CAM software for Milling Today!

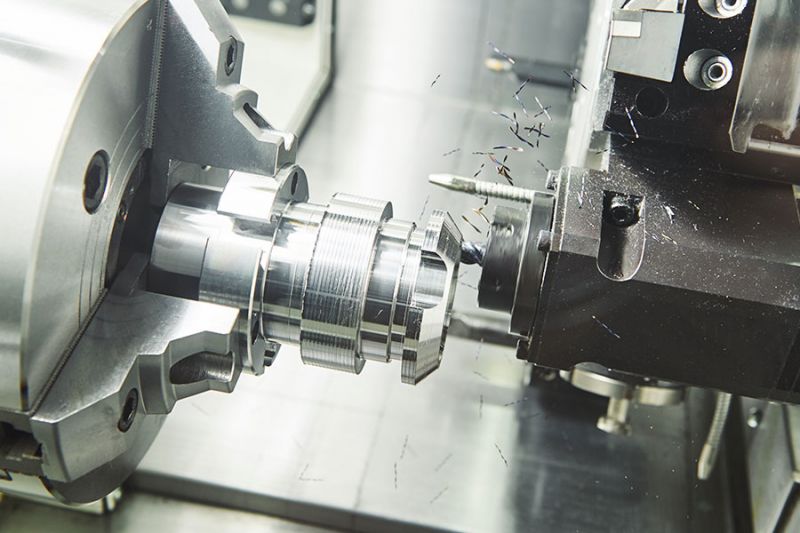

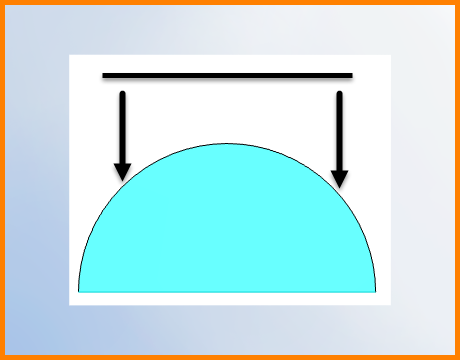

Turning

Multiple turning cycles to rough & finish your parts with options that go beyond traditional canned cycles commonly available on cnc controls. Advance features that minimize geometry editing, limit and control toolpath.

Face Milling

Program machining features on the end of your part like you would with a typical milling center. Drill, Tap, Profile, Pocket, Engrave, Edge break and more. Use long code , Y Axis or polar to match the code output that’s optimal for the operation and control capabilities.

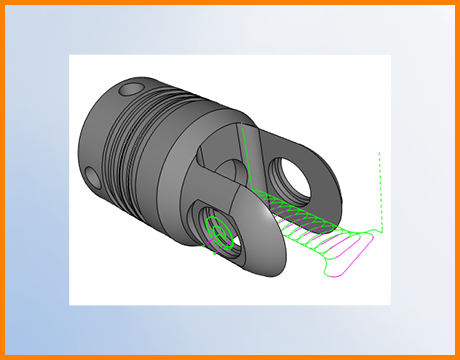

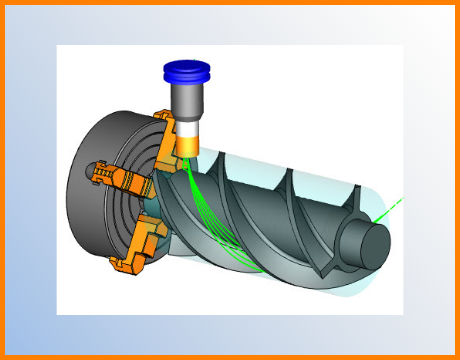

Wrapping Groups

Machine features into the outside diameter of your parts using wrapping groups. Programming with the C axis your tool will be pointed to the axis of rotation. Great for engraving, pockets, slots and more.

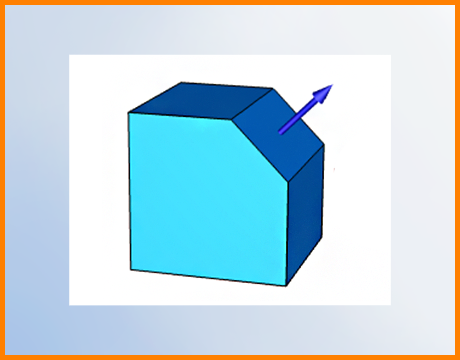

Index Systems

Use index systems to align tool orientation ( clock the part ) for your Y axis programming. Once an index system is established you can use both 2D and 3D toolpath machining features.

2D/3D Toolpaths

Expand your capabilities beyond on board programming cycles when utilizing the full suite of toolpath operations available. Complete 2D and 3D toolpath strategies for roughing, semi finishing and finishing using the same workflow as traditional milling.

4/5 Axis Toolpaths

Advanced simultaneous cutting strategies for expert programming of Multi-task / Milling Head configured machines. Program complex models that require True 4 or 5 Axis. Control tool tilt, run of the tool, angle range limits and more.

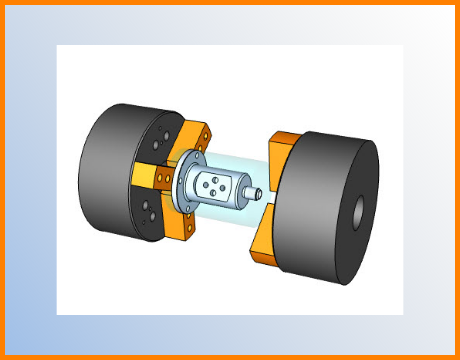

Multi-Spindle & Turrets

Programming on your main or sub-spindle with your upper or lower turret using BobCAD's submachine / work-groups. Supporting up to 10 spindles and 10 turrets.

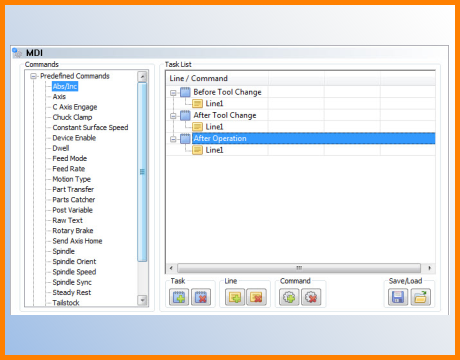

Custom Code Blocks

Why edit your g-code programs after posting to insert special blocks of code when you can use MDI right within the toolpath wizard? Users can add custom or saved blocks of code before & after tool changes or at the end of operations. Used to control turret location, part catchers, steady rests, part transfers and other auxiliary functions.

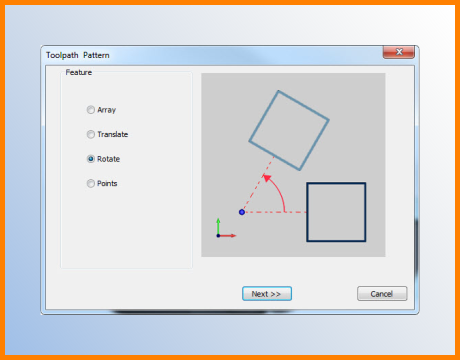

Toolpath Pattern

Reduce your programming time by creating patterns. Allows users to shortcut programming by making copies of machining features where multiple instances occur.

Post Processing

Mill Turn packages require machine specific post processors. Our posting team will build you a custom post processor based supplied samples and machine kinematics. Special functionality can be added using the post processors API, developed in-house or through BobCAD’s posting services.

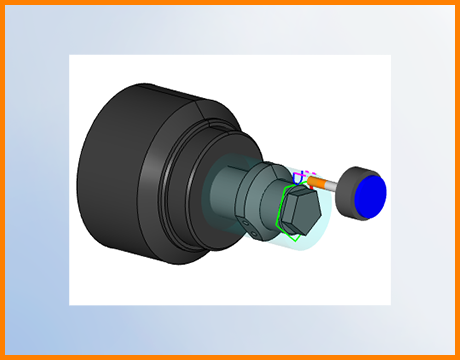

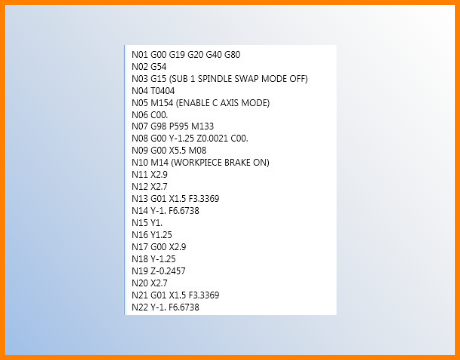

Backplot

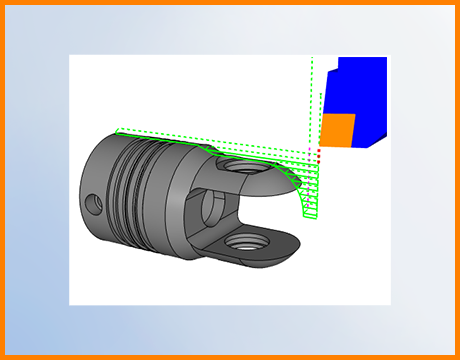

Display your tool and holder as you step through or play your toolpath operation. Rapid graphical feedback for direction of cut, tool hangout, sequence, cutter location, tool orientation and more.

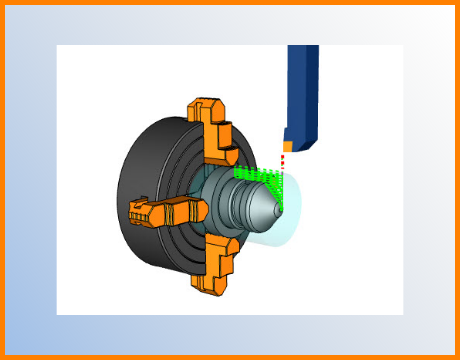

Machine Simulation

Use 3D models to display a “virtual machine” and its components in simulation. Reduce setup time and programming errors by detecting collisions, over travels and more. Find and resolve issues before you ever get out to the machine.

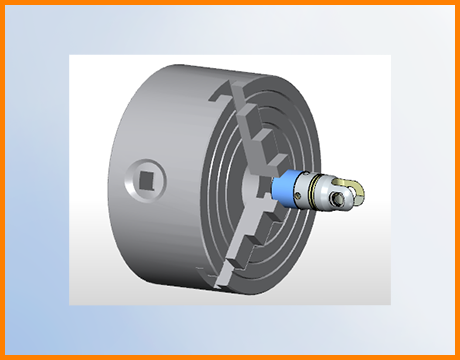

Active Chuck Jaws

Chuck configuration is now available where users can define the chuck and jaws by input or STL files. Jaws will open and close on your part / stock geometry. Visually check chuck jaws for collisions, spinning or if they are properly clocked for part transfers.

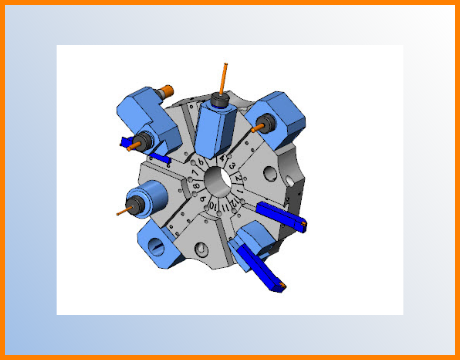

Tool Crib

The Mill Turn tool crib is used to establish, modify and configure your turret with tools, holders, adapters and their mounting orientation. Quickly rearrange configurations by unmounting or moving tool assemblies from one station to another. Use the shelf to store commonly used tools that are not currently in use. Save complete turret configurations for future projects.

OTHER FEATURES INCLUDE

|

Tool Crib

Job Setup Wizard

Dynamic Machining Strategies™

Copy & Paste Operations

Expand & Collapse in Tree

Customizable Setup Sheets

Stock Wizard

Multiple Machine Setups

Material Speed & Feed Library

Tool Holder Library

|

Individual & Compound Drilling Operations

Tool Database

Material Based Calculated Feeds & Speeds

Ability to Save & Load Features

3D Simulation

Work Offset Selection

Coolant Selection

Sub Program Output

3D Arc Fit – G17, G18, & G19 Plane Cutting

Associative CAM Tree

|

|

OD/ID Roughing

OD/ID Finishing

OD/ID Grooving

Drilling

Threading

|

Cut Off with Chamfer & Fillet Corner Break Options

Stock Feed

Pattern Repeat Cycles

Auto-Assignment of Finish Passes

|

|

2.5 Axis

Profiling Pocketing Engraving High Speed Pocketing Thread Milling Plunge Roughing Facing Chamfering Rest Machining 4 Axis

Indexing Wrapping Rotary 5 Axis SWARF Machining High Speed Multiaxis Roughing Trimming Indexing |

3 Axis

3 Axis Wireframe 3 Axis Planar 3 Axis Spiral 3 Axis Engraving 3 Axis Radial 3D Plunge Roughing Z Level Roughing Z Level Finishing Advanced Roughing Flatlands Equidistant Offset Pencil High Speed Roughing Rest Machining Surface Based Toolpath (3, 4, & 5 Axis Output)

Parallel Cuts Cuts Along Curve Morph Between 2 Curves Project Curves Morph Between Surfaces Parallel to Surface |